The battery monitor is an innovative solution for the measurement of battery condition and its communication via PLC or Ethernet. By using multiple frequencies, users will be able to analyze all aspects of the battery in real time, such as internal resistance, current, capacitance and temperature.

This battery monitoring system is an innovative solution to measure battery condition with communication way of Power Line Carrier (PLC). With multi-frequency measurement, users can monitor and analyze battery in all aspects: internal resistance, voltage, current, capacitance, temperature and so on.

BMS-3923 series battery monitoring system is an innovative solution to solve these problems. We apply new methods to measure battery condition with communication way of power line carrier (PLC). With multi-frequency measurement, users can analyze battery in all aspects including internal resistance, voltage, current, capacitance, temperature and so on. Based on Manufactuer years experience for battery management, we build very mature mathematical model that will precisely predict battery capacity. This will in another hand reduce the time that we spend on capacity measurement using a battery load bank. With APP or Web page access based on Cloud server, you could easily manage your batteries simply with a smart phone remotely. Periodically you will receive very detailed diagnostic report indicating comprehensive data of your battery with suggestions and solutions in case of weak batteries.

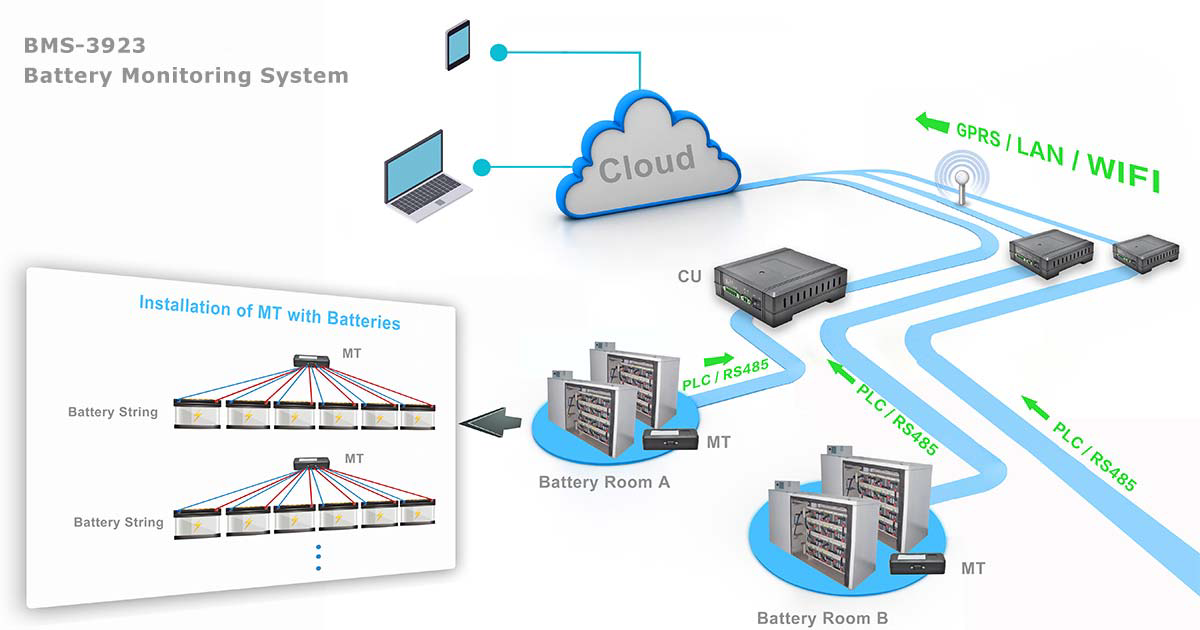

The whole BMS-3923 system is composed of two basic hardware components and one software component. Hardware will include Monitoring Terminal (MT) & Control Unit (CU). With Power Line Carrier (PLC) data transmission, measurement data will be collected by MT simply via battery straps and send to CU. It is no need to have extra time and money consuming communication cable or any other wireless data transmission. This enables the system to be installed in almost all battery systems with very simple wire connection and it is interference-free to battery system.

Monitoring Terminal (MT) Test battery voltage, internal resistance, capacitance & temperature and send to CU via simply via power line carrier (PLC). It has battery equalization function.

Control Unit (CU) Test string voltage, current and collect measurement data from MT simply via power line carrier (PLC). And it will send all data to cloud server via its built-in WiFi/GPRS module.

Contact us by filling out this form: